Products>>3D wire Panel Line>>3D Panel Mesh Production Line

3D Panel Mesh Production Line

3D Panel Mesh Production Line  3D Panel Mesh Welding Line  3D Wire Panel Production Line  3D Panel Mesh Production Line  3D Panel Mesh Welding Line  3D Wire Panel Production Line

|

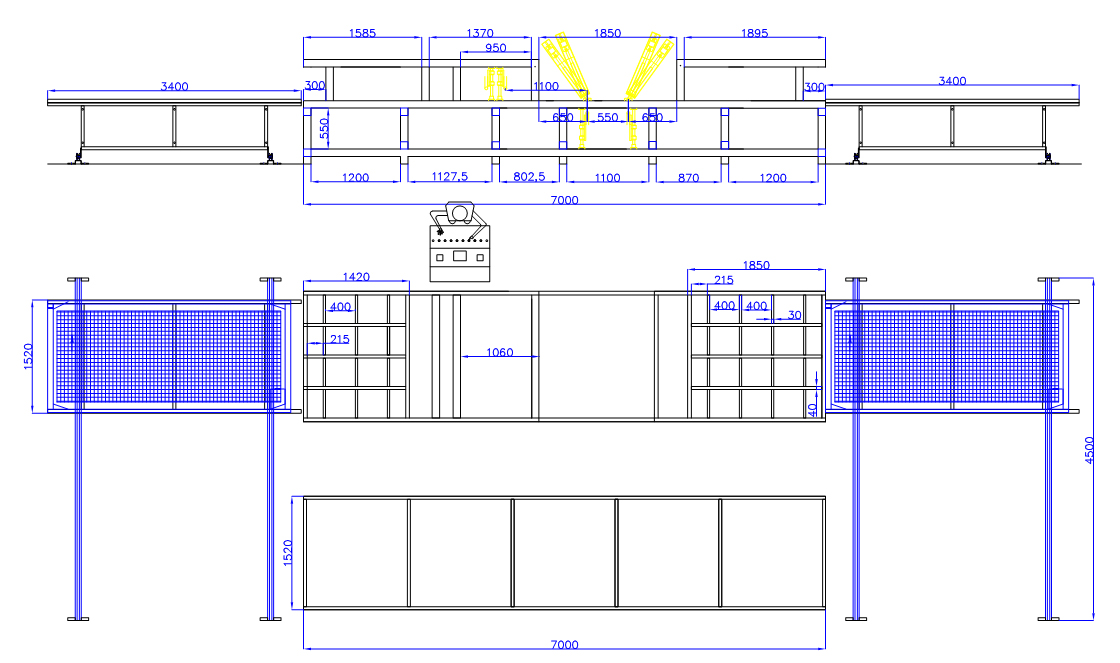

Layout of 3D Panel Production Line:

Description:

The 3D wire mesh panel machine is the main machine of the 3D panel production line, which adopts PLC control system, air cylinder or step motor as drive. It can insert, cut, and control the position of wire mesh and EPS board automatically to complete the production of the 3D panel. 3D wire mesh welding line for the production of reinforcement 3D mesh panels.

This production line is with high automatic manufacturing level, productive efficiency, low lack welding rate, strong welding pressure and strength. The finished products(3D panels) are in excellent quality and low cost.

Specification:

Input power supply: AC380V, 50HZ, 75KVA

Air source equipment: 3m3/min, 0.6Mpa

(1) Standard size:

Wire mesh structure: 50*52mm

Inserting wire diameter: 1.8-2.8mm

Thickness of EPS core: 50-100mm

Structure of inserting wire: single, double wire meshes; sparse, dense inserting

Length: 3000mm

Width: 1220mm

(2) Non-standard size:

Wire mesh structure: 30*30mm, 50*50mm or as requirement;

Inserting wire diameter: 3.0-3.5mm;

Thickness of EPS core: 100-150mm or as requirement;

Max length: 6000mm

Productivity: 3D type(mesh hole 50*50mm)

Dense inserting: 400m2/8 hours

Sparse inserting: 600m2/8 hours

Wire material: galvanized or cold drawing low carbon wire

Material of EPS core: fire resistance type

Max welding rate: 3%

Strength of welding: welding joints(2.5mm wire mesh), min strength: 450N

Machine length: 13500mm

Machine width: 1800mm

Machine height: 1700mm

Machine weight: 4000kgs

Typical 3D panels:

|

|

3D Panel |

3D Welded Wire Panel |