Products>>EPS Production Line>>Layout Of EPS Production Line

Layout Of EPS Production Line

Brief Introduction

EPS is manufactured by combining styrene with isobutylene under pressure. When manufacturing EPS products, tiny beads of polystyrene are expanded and consolidated in the process of steam heating and pressure treatment. When heated, the expanding agent enlarges the beads as much as 40 times, after which they are fused by pressure into huge blocks of EPS. These blocks are cured, then cut and shaped to produce a variety of EPS products, bringing lots of benefits to the construction and packing industries.

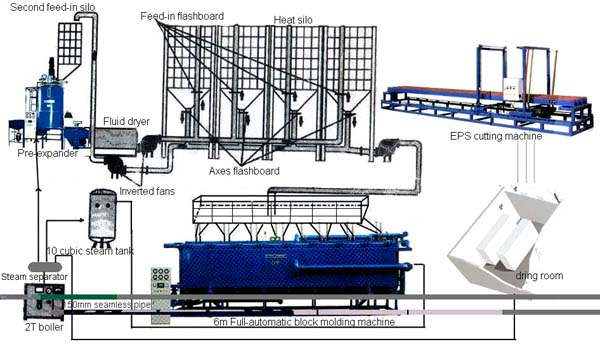

Layout Of EPS Production Line

Main Configuration

1.Pre Expander

2.Intermittence Expander

3.Fluidized Dry Bed

4.EPS foam Block Mould Machine

5.EPS foam Cutting Machine

6.EPS foam Vacuum Shape Mould Machine

Products Typical Applications

|

|

|

Decoration EPS |

EPS Block |

EPS Wall Element |