|

|||||||

EPS Production Line(EPS Machine)

3D Wire Panel LineXPS Board Production LineEPS Sandwich Panel LinePU Sandwich Panel Line |

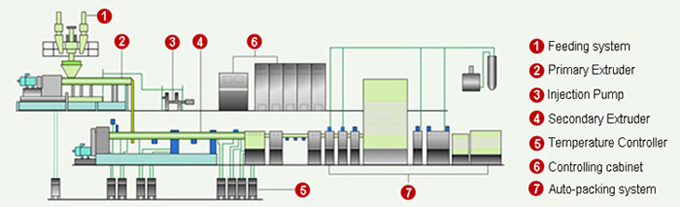

Products>>PU Sandwich>>XPS Board Extrusion LineXPS Board Extrusion Line XPS Board Extrusion Line Description: In the XPS process, polystyrene pellets, like those used to produce rigid sheet for thermoforming, are melted and blended in a regular tandem extrusion system. The extruders pump the melted material through a flat die after the foaming agent (usually based on CO2 or Hydrofluorocarbons - HFC) is injected and homogenized in the primary extruder, the polymer is extruded into secondary extruder for further homogernization and lower temperature. The foaming effect occurs as a result of the change in pressure once the polymer starts exiting the die. It is controlled as the extrudate or hot material expands between adjustable calibrating plates set to the final required thickness. Located after the plates are a train of rollers also helping to control the growth and therefore the thickness while transporting the material forward towards the finishing stations. Quality control measurements for flatness and thickness are performed before the boards are finished. The foamed product must cool and mature before it is ready for the finishing operation. Layout of the XPS board extrusion line:

Main Configuration of the XPS board production line: ♦ Mixer ♦ Screw Extruder ♦ Die ♦ Calibrator ♦ Haul off Unit ♦ Edge Cutter ♦ Cross Cutter Main parameters of the XPS board production line:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||