Products>>EPS Production Line>>EPS Machinery>>EPS Continuous Pre-expander

EPS Continuous Pre-Expander

EPS continuous pre-expander

EPS pre-expander

Technical Parameters of EPS Pre-Expander:

Number |

Items |

Unit |

EPS-CE900 |

EPS-CE1200 |

EPS-CE1600 |

1 |

Dimension of Foaming Tank |

Diameter |

mm |

900 |

1200 |

1600 |

Height |

mm |

2000 |

2200 |

2500 |

2 |

Capacity |

kg/h |

250-400 |

400-800 |

800-1600 |

3 |

Steam Inlet DN |

mm |

25 |

25 |

40 |

4 |

Air-Compressed Inlet DN |

mm |

20 |

20 |

25 |

5 |

Steam Pressure |

Mpa |

0.6 |

0.6 |

0.6 |

6 |

Air-Compressed Pressure |

Mpa |

0.6 |

0.6 |

0.6 |

7 |

Agitation Motor |

Power |

kw |

5.5 |

6.8 |

8.5 |

Rotation |

r/min |

96 |

96 |

96 |

8 |

Max. Contour Size |

mm |

2050¡Á2900¡Á2750 |

2800¡Á1350¡Á2850 |

|

9 |

Machine Weight |

kg |

1500 |

1800 |

2800 |

Main Features of Continuous Pre-Expander for EPS:

- The automation phase of the beads expansion is accomplished by loading the EPS beads into the feeder, expansion of the EPS beads, the expanded EPS beads will then enter the fluidized bed (optional), and then go through the Centrifugal Fan and Conveying device to be transported into the Aging Silos;

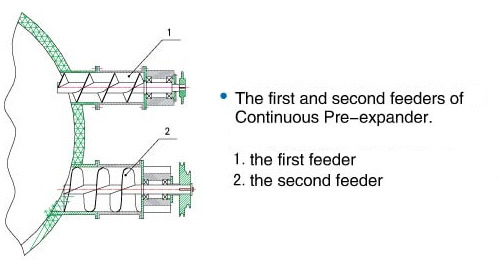

- The machine¡¯s feeder system includes the first-phase and second-phase feeders. The first-phase feeder uses the transformer to regulate the feeding speed, the second-phase feeder uses the method of mobile guide way and wind pipe to blow the EPS Beads to cool down the temperature, ensuring that feeding is stable;

- To accomplish the automatic feeding, the Photoelectric Switch should control the level of the EPS beads in the Automatic Negative Pressure Feeder (Optional).

Product Drawings of EPS Continuous Pre-expander: