Products>>EPS Production Line>>EPS Machinery>>EPS Fluidized Bed

EPS Fluidized Bed

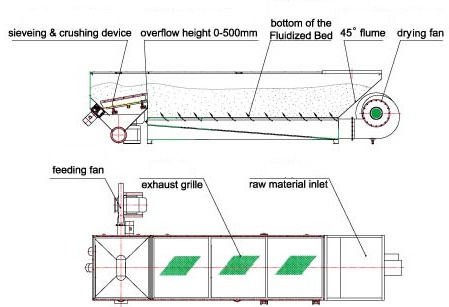

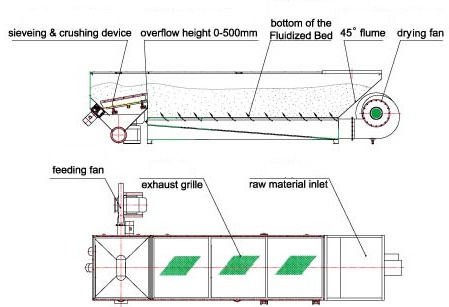

Product Drawing of EPS Fluidized Bed :

Technical Parameters of Fluidized Bed for EPS:

Number |

Items |

Unit |

ABE-LH900 |

ABE-LH1200 |

ABE-LH1600 |

1 |

Steam inlet DN |

mm |

25 |

25 |

40 |

2 |

power |

mm |

5 |

6.6 |

12 |

3 |

Max. Outer Dimension |

mm |

5800X1000X1200 |

6500X1000X1200 |

6500×1500×1820 |

4 |

Machine Weight |

kg |

650 |

700 |

1800 |

Main Features of EPS Fluidized Beds:

1.The machine is attached to the Pre-Expander to form a complete set. This machine uses the high voltage fan and heat exchanger to form the warm air curtain, and then do the dialysis on the pre-expanded EPS beads coming out of the Pre-Expander;

2.

To further improve the expansibility of the pre-expanded beads during the forming process, the bonding property bzhongjieen the beads as well as the elasticity of the beads will help improve the quality of the EPS products;

3.

The temperature within the EPS-FB1200 or EPS-FB1600 fluidized bed dryer, which is attached to the EPSBE1200 Batch Pre-Expander and EPSBE1600 Batch Pre-Expander respectively, can reach 75 ℃, and also use devices such as the vibratory sieve, EPS Block Crusher, and Conveying Fan.